Appendix N. Part 1: A Clear View of Flexible Endoscope Processing: Transport, Leak Testing, Cleaning - Implementation Guide

Slide 1: Appendix N. Part 1: A Clear View of Flexible Endoscope Processing: Transport, Leak Testing, Cleaning

Susan Klacik B.S., CRCST, CIS, FCS

Slide 2: Objectives

After this viewing this video you will be able to—

- List basic endoscope processing steps.

- Explain infection prevention guidelines for transport, leak testing, and cleaning.

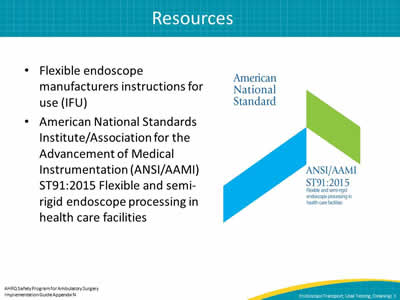

Slide 3: Resources

- Flexible endoscope manufacturers instructions for use (IFU).

- American National Standards Institute/Association for the Advancement of Medical Instrumentation (ANSI/AAMI) ST91:2015 Flexible and semi-rigid endoscope processing in health care facilities.

Image: Cover of ANSI/AAMI ST91:2015 Flexible and semi-rigid endoscope processing in health care facilities.

Slide 4: Basic Endoscope Processing Steps

- Precleaning at the point of use

- Transporting

- Leak testing

- Cleaning

- Rinsing

- Inspecting or testing for cleanliness, where applicable.

- Disinfection/high-level disinfection and monitoring of the process, where applicable.

- Rinsing

- Drying and alcohol flush.

- Storage

Slide 5: Point of Use Precleaning IFU

- Importance of precleaning.

- Equipment needed.

- Process to use.

- Specific measurements.

- Specific times to suction fluids.

Slide 6: Point of Use Precleaning ST91

To prevent buildup of bioburden, development of biofilms, and drying of secretions, precleaning should take place at the point of use immediately following the procedure.

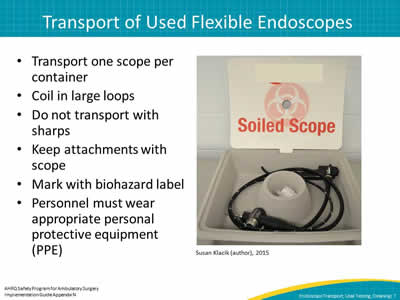

Slide 7: Transport of Used Flexible Endoscopes

- Transport one scope per container.

- Coil in large loops.

- Do not transport with sharps.

- Keep attachments with scope.

- Mark with biohazard label.

- Personnel must wear appropriate personal protective equipment (PPE).

Susan Klacik (author), 2015

Slide 8: Transport of Used Scopes - Continued

Personnel must wear PPE

The attachments stay with the scope

Susan Klacik (author), 2015

Images: staff in personal protective equipment and attachments to the scope

Slide 9: Leak Testing IFU

- Specify equipment needed.

- Provide instructions on how to connect and disconnect.

- Identify leaks.

- Provide instructions on what to do if a leak is detected.

Susan Klacik (author), 2015

Image: leak testing of a scope

Slide 10: Leak Testing ST91

- Perform as soon as possible.

- Scope minimally coiled.

- Overcoiling can mask a hole and allow it to go undetected.

- Work surface should be well lighted.

- Allow sufficient time.

Susan Klacik (author), 2015

Image: leak testing of a scope

Slide 11: Manual Cleaning IFU

- Equipment needed.

- Type of cleaning solution.

- Measurement of solution.

- Time of solution contact.

- Step-by step process.

- Delayed processing.

Susan Klacik (author), 2015

Image: equipment being manually cleaned

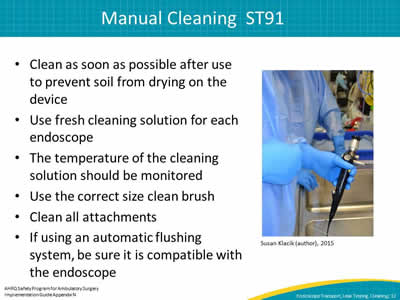

Slide 12: Manual Cleaning ST91

- Clean as soon as possible after use to prevent soil from drying on the device.

- Use fresh cleaning solution for each endoscope.

- The temperature of the cleaning solution should be monitored.

- Use the correct size clean brush.

- Clean all attachments.

- If using an automatic flushing system, be sure it is compatible with the endoscope.

Susan Klacik (author), 2015

Image: showing brush channel

Slide 13: Rinsing IFU

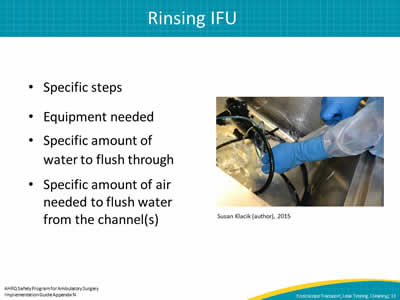

- Specific steps.

- Equipment needed.

- Specific amount of water to flush through.

- Specific amount of air needed to flush water from the channel(s).

Susan Klacik (author), 2015

Image: Equipment being rinsed

Slide 14: Rinsing ST91

- After cleaning, thoroughly rinse scope and accessories with copious amounts of tap water.

- Rinse all exterior endoscope surfaces with freely flowing potable water.

- Purge channels with air using a syringe to evacuate residual rinse water.

- Remove rinse water from the channels by purging channels with air using a syringe.

Slide 15: Inspecting for Cleanliness

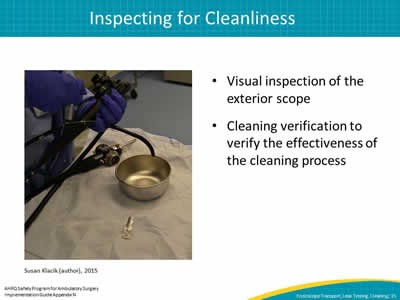

- Visual inspection of the exterior scope.

- Cleaning verification to verify the effectiveness of the cleaning process.

Susan Klacik (author), 2015

Image: showing visual insection and cleaning verification

Slide 16: References

- American National Standards Institute and Association for the Advancement of Medical Instrumentation. ANSI/AAMI ST91:2015 Flexible and semi-rigid endoscope processing in health care facilities. 2015. http://www.aami.org/productspublications/ProductDetail.aspx?ItemNumber=2477.