Appendix O. Part 2: A Clear View of Flexible Endoscope Processing: Disinfection/Sterilization Record Keeping - Implementation Guide

Slide 1: Appendix O. Part 2: A Clear View of Flexible Endoscope Processing: Disinfection/Sterilization Record Keeping

Susan Klacik B.S., CRCST, CIS, FCS

Slide 2: Objectives

After viewing this video you will be able to—

- List basic endoscope processing steps.

- Explain infection prevention guidelines for scope disinfection/sterilization, record keeping, and scope storage.

Slide 3: High-Level Disinfection/Sterilization: Instructions for Use (IFU)

- Equipment needed.

- Type of high-level disinfectant (HLD)/sterilants compatible with scope.

- Measurement of solution.

- Specific steps for thorough rinsing.

- Exact measurements for rinsing.

- Step-by step process.

Slide 4: High-Level Disinfection

- Don fresh personal protective equipment (PPE), including gloves and skin and eye protection.

- Use a closed container labeled with a biohazard symbol.

- The container should be large enough to completely immerse the endoscope in the liquid chemical sterilant (LCS)/HLD solution.

- Prepare according to the manufacturer's written IFU.

- Document:

– name of solution

– expiration date

– date of preparation

– date of use - Test the minimum recommended concentration (MRC) before each use with the disinfectant-specific test strip.

- Follow the label directions for the test strip.

- Document results.

Slide 5: Automatic Endoscope Reprocessor (AER)

- Check to ensure the scope can be processed

– Validated.

– Compatible with high-level disinfectant. - PPE used for decontamination should not be worn when handling a scope or any of the accessories after they have gone through the disinfection process.

Slide 6: Automatic Endoscope Reprocessor (AER)

- Incoming water should be filtered using bacterial retentive filters as recommended in the AER manufacturer's written IFU.

- Quality testing devices are available for many AERs to ensure the solutions are flowing.

- Testing should be performed at least weekly, after major repairs, or whenever there is a concern about equipment function.

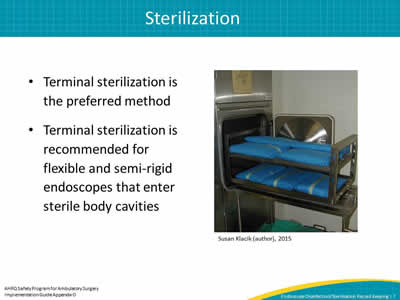

Slide 7: Sterilization

- Terminal sterilization is the preferred method.

- Terminal sterilization is recommended for flexible and semi-rigid endoscopes that enter sterile body cavities.

Susan Klacik (author), 2015

Image: showing sterilization

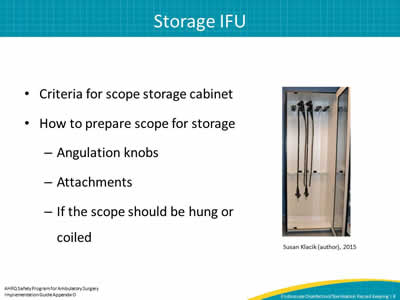

Slide 8: Storage IFU

- Criteria for scope storage cabinet.

- How to prepare scope for storage

– Angulation knobs.

– Attachments.

– If the scope should be hung or coiled.

Susan Klacik (author), 2015

Image: photo of scope storage

Slide 9: Storage ST91

- Store hanging vertically with the distal tip hanging freely in a clean well-ventilated cabinet.

- Angulation lock should be in the open position.

- Leave sufficient space around scopes to prevent them hitting into one another.

- All removable parts (e.g., valves and caps) should be detached and kept with the scope.

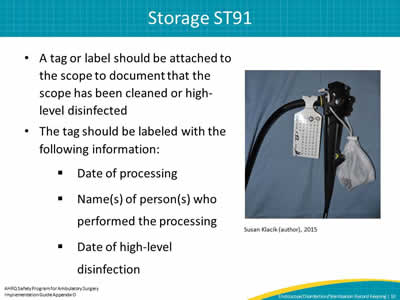

Slide 10: Storage ST91

- A tag or label should be attached to the scope to document that the scope has been cleaned or high-level disinfected.

- The tag should be labeled with the following information:

- Date of processing.

- Name(s) of person(s) who performed the processing.

- Date of high-level disinfection.

Susan Klacik (author), 2015

Image: Tag or label shows the scope has been cleaned or disinfected

Slide 11: Storage ST91

- Channels should be dry to help prevent bacterial growth and biofilm formation.

- To help ensure that no moisture is left on or in any part of the endoscope, all channels should be flushed with 70–80 percent alcohol to facilitate drying.

- All channels should be purged with filtered medical-grade air at the correct pressure.

- Temperature and humidity in the area where the scopes are stored should be monitored.

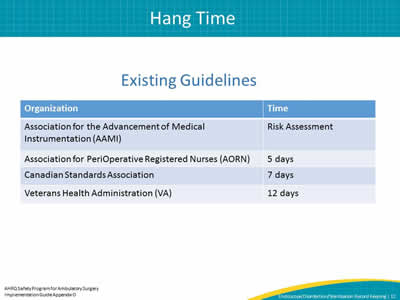

Slide 12: Hang Time

Existing Guidelines

| Organization | Time |

|---|---|

| Association for the Advancement of Medical Instrumentation (AAMI) | Risk Assessment |

| Association for PeriOperative Registered Nurses (AORN) | 5 days |

| Canadian Standards Association | 7 days |

| Veterans Health Administration (VA) | 12 days |

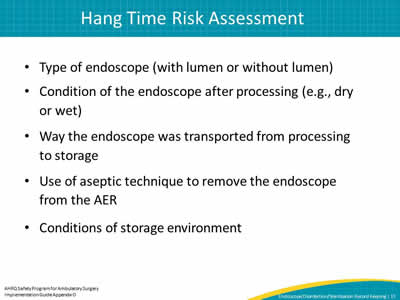

Slide 13: Hang Time Risk Assessment

- Type of endoscope (with lumen or without lumen).

- Condition of the endoscope after processing (e.g., dry or wet).

- Way the endoscope was transported from processing to storage.

- Use of aseptic technique to remove the endoscope from the AER.

- Conditions of storage environment.

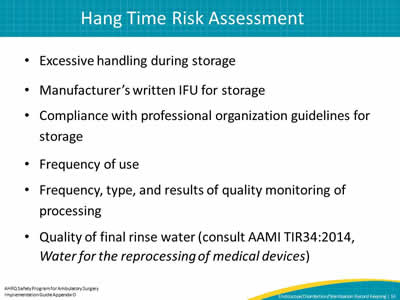

Slide 14: Hang Time Risk Assessment

- Excessive handling during storage.

- Manufacturer’s written IFU for storage.

- Compliance with professional organization guidelines for storage.

- Frequency of use.

- Frequency, type, and results of quality monitoring of processing.

- Quality of final rinse water (consult AAMI TIR34:2014, Water for the reprocessing of medical devices).

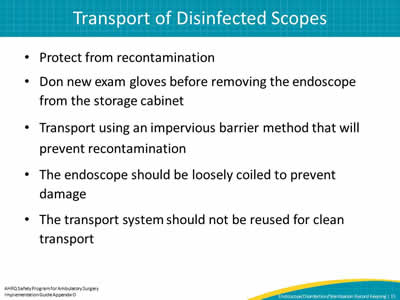

Slide 15: Transport of Disinfected Scopes

- Protect from recontamination.

- Don new exam gloves before removing the endoscope from the storage cabinet.

- Transport using an impervious barrier method that will prevent recontamination.

- The endoscope should be loosely coiled to prevent damage.

- The transport system should not be reused for clean transport.

Slide 16: Quality Control Ability To Track Scope Use

Identify—

- The sterilizer, AER, or soaking container.

- The date chemical sterilization or high-level disinfection was performed.

- The sterilization or high-level disinfection cycle number.

- Patient identifier.

Slide 17: Record Keeping

- Lot number.

- Specific name of the item.

- Patient identifier.

- Procedure/physician.

- LCS/HLD expiration date.

- Exposure time and temperature.

- Cycle date & time.

- Name of LCS/HLD.

- Name/initials of person performing HLD/sterilization.

- Results of quality monitoring testing.

Slide 18: References

- American National Standards Institute and Association for the Advancement of Medical Instrumentation. ANSI/AAMI ST91:2015 Flexible and semi-rigid endoscope processing in health care facilities. 2015. http://www.aami.org/productspublications/ProductDetail.aspx?ItemNumber=2477.